Core technologies

It has been 100 years since we have driven a motor.

Yaskawa’s DNA is to be a technology-driven company. The company is committed to developing new technologies for “motors and their application” every day.

It has been 100 years since we have driven a motor.

Yaskawa’s DNA is to be a technology-driven company. The company is committed to developing new technologies for “motors and their application” every day.

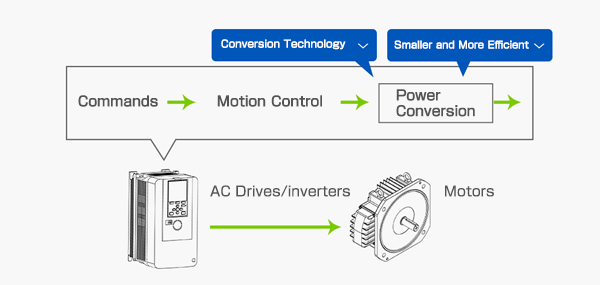

One of Yaskawa’s three core technologies is power conversion, which converts supplied power into appropriate power. Power conversion is required to generate the power needed to run electric equipment, such as motors. Furthermore, it is necessary to convert power when using power supplied by a generator. Power conversion technology is used in servos and AC Drives/inverters that run industrial equipment, power conditioners that supply power from solar cells, and Electric Vehicles (EVs).

The power conversion technology, which controls the voltage, current, and frequency of the input power supply to convert it to the intended output, has been applied to several of our products, including AC Drives/inverters.

The AC Drive/inverter converts AC voltage to DC voltage through a rectifier circuit and performs reverse conversion to convert the DC voltage to any AC voltage and frequency. During the reverse conversion, conversion losses, such as conduction losses due to the internal resistance of the semiconductor device and switching losses due to switching delays, result in lower conversion efficiency. We develop switching control technology and new device application technology to reduce this conversion loss, leading to higher efficiency and smaller AC Drives/inverters.