The Autonomous Improvement by Utilizing Food Factories’ Data through “i3-Mechatronics” Concept

- Application of Robots to Realize Kewpie’s “Future Food Factory” -

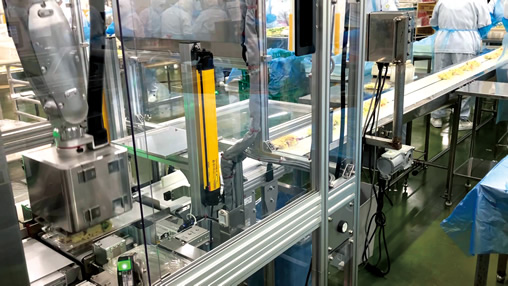

Kewpie has been promoting the automation of production processes to improve quality and productivity through the use of data, with the aim of achieving sustainable growth under the banner of “Future Food Factory.” Yaskawa has promoted technological development while sharing the concept “autonomous improvement through automation of cells and equipment and utilization of data in high-mix, low-volume production lines” with Kewpie. In November 2023, a robot applicable to a cell to close the lid of deli dishes was started operation. Moreover, we are working toward implementing a system in which the robot itself performs a total inspection of the lid-closing state by utilizing torque and position data obtained from the robot hand.”

Challenges

The labor shortage is a major issue in food factories. The delicatessen factory can produce 400 kinds of delicatessen a day in a small quantity, and the factory is required to have the same level of workability as a human worker (speed and space saving), 365-day, 24-hour operation, and low cost. In particular, Kewpie had to rely on manual labor to close the lid of containers because of frequent changes in the setting for containers of various sizes and shapes.

Previously, the delicatessen factory had no experience with robots and no engineers who could handle them.

Details of initiatives

Yaskawa aims to solve customer challenges by utilizing data obtained from production sites and driving improvements through i3-Mechatronics. We offered proposals that meet Kewpie’s needs and our positive attitude was recognized, which led to this collaboration.

Yaskawa had greatly contributed its experience and knowledge cultivated outside the food market, such as in electronics and auto-mobiles, and the cooperated in the development of the necessary element technologies and mechanisms. The lid closing robot uses a hand attached to the robot arm to grasp and attach lids onto containers in the cell. Excluding variations in containers and ingredients, the success rate of lid-closing robots is almost 100%.

Also, it was required to be “Easy to Use”* so that it could be operated even when an engineer was absent, and the panel was equipped with a variety of user-friendly functions, such as “having only three operation buttons” and “variety registration can be done easily on site.”

In addition, we are working to realize a system in which the robot itself inspects the state of all lids using torque and position data from the servo motors attached to the robot hand. If a lid‑closing fails, the robot automatically retries. If the lid still cannot be closed after the retry, the robot signals for the item to be removed in the subsequent process. Therefore, humans or inspection devices do not have to check the robot’s work results.

* Easy to Use:Worker friendly operation

Customer’s voice

It is a great achievement that the intuition and skills of the workers have been automated, and we could move on to the horizontal deployment phase. The three elements realized by the lid closing robot, “Multi-product compatibility,” “Workability at the same level as humans,” and “Easy to use,” are essential elements for automating processes common to all Group companies, such as loading and stacking. We are going to apply these knowledges to other production sites. Specifically, we are planning to automate the loading of palletizers. The loading process at mass-production plants is automated, but at high-mix low-volume production plants, there are issues such as adapting to small numbers of products and cooperating in space-saving operations, and we are still relying on manual labor. We look forward to the further proposals from Yaskawa.

In addition, from the perspective of quality assurance, we believe that robotization has significant advantages. There are many processes for inspection devices to check the work results of automatic equipment, but from a cost perspective, it would be extremely useful to be able to guarantee the full amount of work with only the functions of the robot without the need for additional devices. Furthermore, if the robot learns the data currently being collected for inspection, and if it can reflect this in its movements, such as automatically “increasing the pressure applied” when it finds a part of the lid that is difficult to close, it will be possible to perform work in a manner similar to that of a human.

The collaboration with Yaskawa gives us a sense of the feasibility of such technology.

Company Profile

Kewpie Corporation

Address: Shibuya-Ku, Tokyo Japan

Business: Manufacture and sale of “mayonnaise sauce”, other general sauces and food

URL : https://www.kewpie.com/en/

Related link

Here are some other examples.

Bestact Solutions Inc.

-Stabilizing the Quality of Bestact Products

RoadPrintz Inc.

-Road painting system by truck mounted with robot

Yasuda Yogurt Co., Ltd

-Yogurt Cartons Palletizing

HINODE,Ltd.

-Deburring of Manhole Frame

Region

Region

Principles & vision

Principles & vision

Procurement

Procurement

Sustainability for the Yaskawa Group

Sustainability for the Yaskawa Group

Customer satisfaction

Customer satisfaction

Supply chain

Supply chain

Social contribution

Social contribution

Compliance & risk management

Compliance & risk management