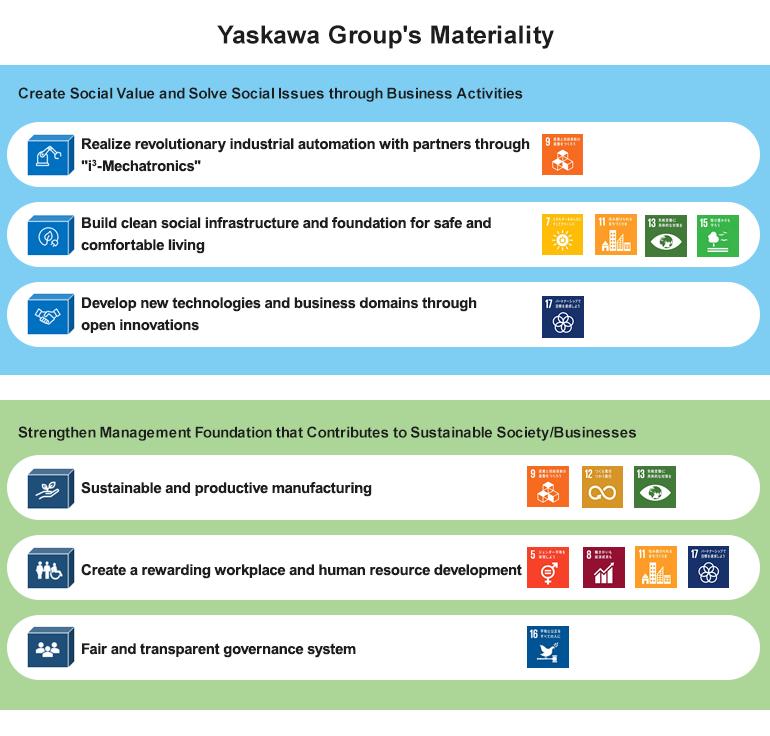

Sustainability challenges and targets

In regard to sustainability challenges and targets (materiality), we identified issues of high importance by evaluating trends in the international community and social issues that are closely related to us from two perspectives: ① importance to stakeholders, ② importance to YASKAWA.

These issues were discussed at internal meetings, including those of the Board of Directors, and issues of particular importance were identified as materiality. We have also clarified the direction of each focus area and strategy, and set quantitative and qualitative KPIs. Through the resolution of identified materiality issues, we are working to realize a sustainable society and increase corporate value, which we aim to achieve under our sustainability policy.

Sustainability Challenges and Targets(Materiality)and Their Progress

Create Social Value and Solve Social Issues through Business Activities

| Materiality |

Realize revolutionary industrial automation with partners through “i3-Mechatronics” |

Desired

Outcomes |

Solve customer management issues with “i3-Mechatronics,” a solution concept and contribute to the improvement and evolution of society and production activities |

| Initiatives |

Accumulation of “i3-Mechatronics” project success cases |

FY2023

Results |

- • Strengthened customer approach with key products

(MOTOMAN NEXT series, YRM-X controller, Sigma-X series, YASKAWA Cockpit) based on i3-Mechatronics concept

- • Expansion of results through collaboration with top manufacturers in each industry

|

| Materiality |

Build clean social infrastructure and foundation for safe and comfortable living |

Desired

Outcomes |

- (a) Use Yaskawa’s technological capabilities to improve the environmental performance of products and reduce the environmental impact of the world by expanding sales

- (b) Contribute to the realization of a sustainable society through the challenge of developing new domains by applying mechatronics technology

|

Initiatives

[Targets] |

- (a) Achieve CCE 100 (Contribution to Cool Earth 100)*1

[FY2025: 100 times]

- (b) Expand examples of mechatronics technology applications, mainly in the four fields of energy conservation, clean power, food and agriculture, and biomedical

|

FY2023

Results |

- (a) 113.9 times

- (b) Promoted initiatives in mechatronics application fields, focusing on the four main fields

• Launched GA700 series of AC drives with large-capacity

• Launched PV inverter for solar power generation, “Enewell-SOL P3A”

|

| Materiality |

Develop new technologies and business domains through open innovations |

Desired

Outcomes |

- (a) Create new value for society through business expansion in new areas through M & A/alliances

- (b) Promote external collaboration to develop the world’s first and best technologies and products

- (c) Demonstrate business synergies through venture investment and collaboration

|

| Initiatives |

- (a) Strengthen initiatives in new areas through M & A and alliances

- (b) Reinforcement of Industry-Academia-Government collaboration

- (c) Expansion of venture investments by YIP*2

|

FY2023

Results |

- (a) Continued aggressive search for growth opportunities through M&A/alliances to create technological synergies in our company’s business areas of factory automation and

mechatronics applications

• Moved “automation of cucumber leaf removing work,” which is being developed in collaboration with JA ZEN-NOH to the full-fledged introduction phase

• Promoted automation of plant factories through a capital and business alliance with Oishii Farm Corporation in the U.S.

- (b)Promoting Industry-Academia-Government collaboration in and outside Japan on research and development that contributes to our company’s future technologies

- (c) Venture investments: 1 (Cumulative number: 20)

|

Strengthen Management Foundation that Contributes to Sustainable Society/Businesses

| Materiality |

Sustainable and productive manufacturing |

Desired

Outcomes |

- (a) Promote global production efficiency and optimization through domestic and overseas expansion of the “Yaskawa Solution Factory” concept

- (b) Reduce CO2 emissions and address global climate change issues

- (c) Provide optimal maintenance throughout the life cycle with the ultimate goal of “not stopping customer equipment”

- (d) Implement supply chain management based on adherence to sustainable procurement guidelines

|

Initiatives

[Targets] |

- (a) Introduction of cutting-edge manufacturing

• Improving production efficiency at own plants (improving productivity indicators*3)

[FY2022: +19%*4 FY2025: +34%*5 (compared to FY2019)]

- (b) Reduction of greenhouse gas emission through the Green Process

• Reducing greenhouse gas (CO2) emissions

[FY2025: -30%*6 (compared to FY2018)]

- (c) Improvement of product safety and quality

• Product safety through our group’s Product Liability Committee

[Fiscal 2022: Strengthening global development of activities to pinch off the “bud of PL”]*7

• Improving product quality through the introduction of new systems

[FY2022: Start of global operation of market quality information centralized system]

- (d) Construction of a sustainable supply chain

• Improving the rate of compliance with Sustainable Procurement Guidelines

[FY2022: Compliance rate: 100%*4

(target: major suppliers of Yaskawa Electric)

FY2025: Compliance rate: 100%

(target: major suppliers of Yaskawa Group)]

|

FY2023

Results |

- (a) Productivity indicators: +21% (compared to FY2019)

- (b) -18.6% (compared to FY2018)

- (c)

• Global development of activities to pinch off the “bud of PL” (No. of buds: 29, The number of risk assessments completed (target: 15, completed: 100%)

• Centralization of quality information on a global scale (start of operations in China)

- (d) Support for developing sustainable procurement policies and establishing guidelines for 2 overseas group companies

|

| Materiality |

Create a rewarding workplace and human resource development |

Desired

Outcomes |

- (a) Demonstrate the strengths of diverse human resources by promoting the active participation of women

- (b) Develop human resources based on personnel philosophy and improve the job satisfaction of employees

- (c) Eliminate work stoppage accidents and create a safe workplace

- (d) Aim for the sustainable development of the company and its employees by improving productivity by creating an environment in which each employee can work with peace of mind and make the most of his or her abilities

- (e) Raise employees’ awareness of human rights and create a workplace where human rights are respected

- (f) Promote social contribution activities to coexist and co-create with local communities by developing human resources for the evolution of manufacturing

|

Initiatives

[Targets] |

- (a) Diversity and inclusion

• Raising the ratio of female managers

[FY2025: Non-consolidated/Group in Japan: 3.4%*8]

- (b) Human resource development

• Increase the ratio of professional human resources*9

[FY2025: Corporate average 20% or more*10]

- (c) Occupational safety and health

• Improvement of lost-time injury frequency rate

[FY2025: Non-consolidated: Maintain 0.2 or less

Major production bases in Japan and overseas: Maintain 0.4 or less]

- (d) Health management*11

• Improvement of indicators for the realization of health management

- (e) Human rights and work practices

• Implementation and establishment of human rights due diligence processes for employees

[FY2022: Implementation of human rights due diligence for group companies in Japan

FY2025: Consideration of measures to meet the requirements of EU sustainability laws*12]

- (f) Contribution to local communities

• Development of human resources in science and engineering who will realize “evolution of manufacturing”

[FY2022: Launch of a new manufacturing human resource development program]

|

FY2023

Results |

- (a) Ratio of female managers: 2.4% (non-consolidated), 2.6% (domestic group)

- (b) The ratio of professional human resources: 15%

- (c) Lost time injury frequency rate: 0.16 (non-consolidated), 0.44 (domestic group), 0.56(global)

- (d) Completion of setting of indicators (10 items) for the realization of health management and acquisition of certification as Excellent Health Management Corporations 2024

- (e) Non-consolidated: Continued implementation of human rights due diligence

Domestic: Introduction of human rights due diligence at affiliated companies

Overseas: Assessment of current status at major sites

- (f) Completion of planning of a new program (robot kit assembly, programming, and cooperative work with robots operating in YASKAWA Innovation Center)

|

| Materiality |

Fair and transparent governance system |

Desired

Outcomes |

- (a) Promote sustainable growth and increase corporate value through constructive dialogue with investors

- (b) Raise the level of the security organization and build an autonomous and continuous information security system

- (c) Prevent escalation by early detection of compliance risks

|

Initiatives

[Targets] |

- (a) “Aggressive” governance system utilizing the Corporate Governance Code

• Implementation of the Principles of the Corporate Governance Code (Reasonable explanation where not implemented)

- (b) Strengthening of information security

• Internal and external security monitoring/measures in systems and security level evaluation/improvement by external auditing organizations

- (c) Enhancement of compliance

• Strengthen compliance through internal reporting

• Strengthen cooperation by holding meetings with compliance officers overseas

|

FY2023

Results |

- (a) Implementation of the principles of the Corporate Governance Code required of companies listed in “prime market”

- (b)

• Strengthened information security personnel and global SOC (Security Operation Center) monitoring by utilizing security threat analysis services

• Early detection of potential risks and implementation of countermeasures

• Security audits for global sites and response to information security legislation in overseas countries

- (c)

• Appropriate responses to internal reporting and other compliance issues

• Shared issues by meeting with compliance officers, including those overseas

|

*1 Target to reduce CO2 emissions from our products by more than 100 times by 2025.

*2 Abbreviation of Yaskawa Innovation Program. New business creation scheme with CVC functions launched in FY2016.

*3 Revenue per person for indirect and direct personnel at plants in Japan (compared to FY2019).

*4 Target was revised in April 2022.

*5 Target was revised in April 2024.

*6 The target value was changed following the revision of the 2050 carbon neutral target in May 2022.

*7 Target was set in October 2022.

*8 Target was revised in June 2024.

*9 A person at the level of being able to teach others in the skills within a task to which he or she is assigned

*10 Definition of professional human resources and target values were revised in June 2024.

*11 Initiatives were added in April 2024.

*12 Target was revised in April 2024.

Region

Region

Principles & vision

Principles & vision

Procurement

Procurement

Sustainability for the Yaskawa Group

Sustainability for the Yaskawa Group

Customer satisfaction

Customer satisfaction

Supply chain

Supply chain

Social contribution

Social contribution

Compliance & risk management

Compliance & risk management