In 2024, the company began taking measures to stabilize quality by utilizing data on equipment operation and production.

What is Bestact?

Bestact is a high-power reed switch with junctions encapsulated in a glass tube. It is a unique product of Bestact Solutions Inc. It offers excellent environmental resistance, a long product lifespan, and extremely high junction reliability. Therefore, it is used in various industrial fields, including railways, steel, electric power, and elevators.

Challenge to maintain production quality

Bestact is a highly precise product, and as such, variations in quality are inevitable due to factors such as differences in component tolerances and materials, as well as wear and deterioration of production equipment. To achieve the desired quality, we fine-tune our equipment and perform manual adjustments. However, in order to meet the specific quality characteristics demanded by our customers, it was essential to further enhance the precision of our processing and assembly technologies.

Details of initiatives

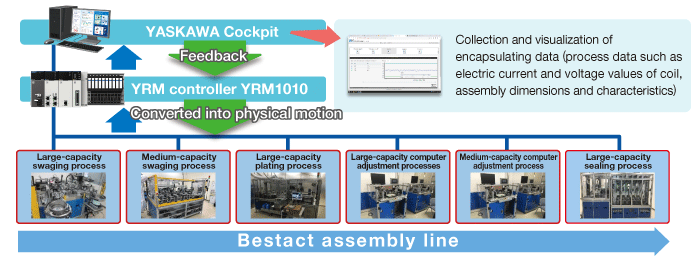

In addition to manufacturing automation, it is crucial to utilize digital data generated during machinery and equipment operation to achieve stable and high-quality production. We aimed to produce the desired quality by analyzing data from the Bestact manufacturing site in real time and feeding the results back to control operations.

First, the YRM controller, acting as an integrated controller, collected data on the facility’s operational and production status. Meanwhile, the YASKAWA Cockpit, serving as a visualization tool, visualized and analyzed the facility’s operational status. As a result, it was found that thermal energy during the coil sealing process was uneven. Accordingly, fluctuations in thermal energy—such as current and voltage—are now monitored and controlled in real time. This not only made it possible to reduce defects, but also enabled early detection and recovery from equipment abnormalities, leading to a reduction in downtime losses.

Image of i3-Mechatronics in action

Voice of the person in charge

Currently, the main equipment on the Bestact assembly line is connected to the YRM controller, and data is collected from each piece of equipment in real time. In the future, we plan to develop an add-on application for YASKAWA Cockpit to further visualize quality and characteristic data, and analyze influencing factors that affect product characteristics to improve quality.

Company Profile

Bestact Solutions Inc.

Address: 2-13-1 Nishimiyaichi, Yukuhashi, Fukuoka, Japan

Business: Manufacturing and sales of Bestact reed switches

URL : https://www.bestact.co.jp/gl

Installed products

Related link

Here are some other examples.

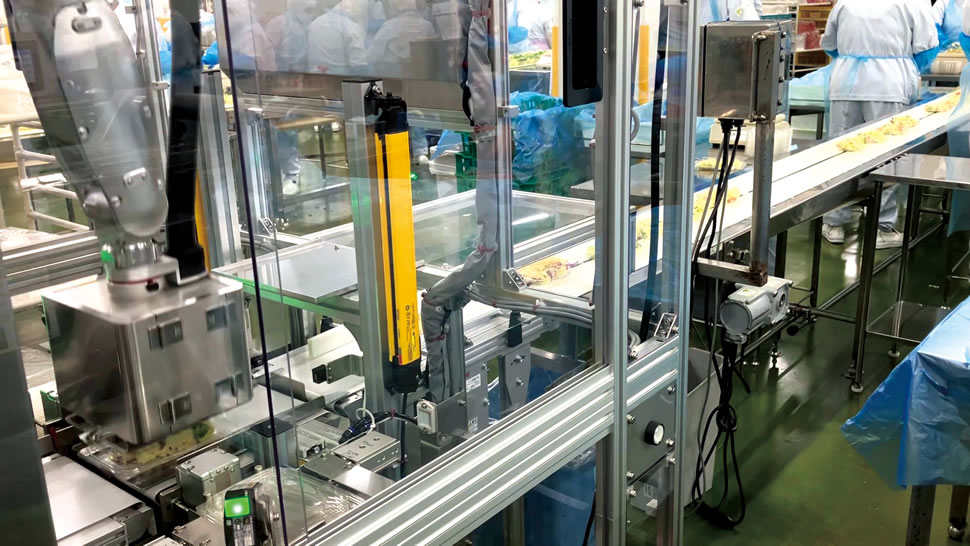

Kewpie Corporation

-The Autonomous Improvement by Utilizing Food Factories’ Data

RoadPrintz Inc.

-Road painting system by truck mounted with robot

Yasuda Yogurt Co., Ltd

-Yogurt Cartons Palletizing

HINODE,Ltd.

-Deburring of Manhole Frame

Region

Region

Principles & vision

Principles & vision

Procurement

Procurement

Sustainability for the Yaskawa Group

Sustainability for the Yaskawa Group

Customer satisfaction

Customer satisfaction

Supply chain

Supply chain

Social contribution

Social contribution

Compliance & risk management

Compliance & risk management