What is a Collaborative Robot?

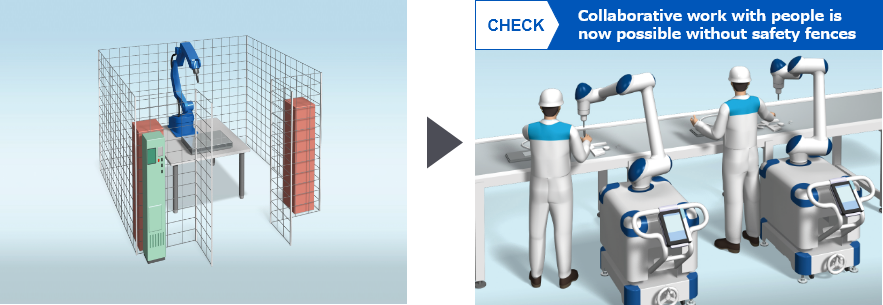

A collaborative robot is an emerging category of robots designed to work together while sharing the same space with humans, not having to be isolated by a fence for safety. Conventional industrial robots are often used for 3D tasks that are difficult or dangerous for humans. Meanwhile, collaborative robots are designed to work with humans through various designs that consider the safety of people working in the same space.

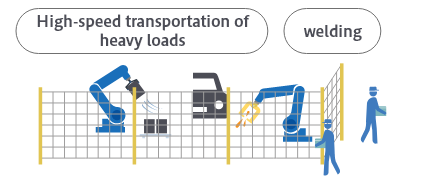

Conventional industrial robot

- The conventional industrila robot is used for difficult and dangerous tasks for humans.

- This robot is robust, fast to move, and powerful to produce.

- This robot should be isolated from humans by safety fences, because contact with people could result in a major incident.

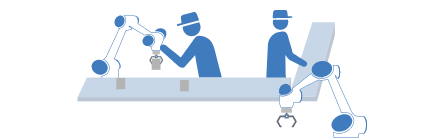

Collaborative robot

- Collaborative robots are used for tasks performed in the same space as people.

- Collaborative robots are designed in a variety of ways considering human safety, such as stopping immediately upon contact with a person or keeping the speed of movement below a certain level.

- Collaborative robots are designed to be safe in contact with people, so they don’t have to be separated.

Basic expertise in collaborative robots

The past difficulty of installing conventional robots

Many people think of industrial robots as scenes used in welding and painting in automobile factories. Recently, however, robots have been used in many fields other than automobiles and electronic components, including logistics and food factories, as well as the pharmaceutical, cosmetic, home appliance assembly and construction industries. The shortage of manpower at manufacturing sites around the world has become a serious problem in recent years, and automation using robots is increasingly required. In addition, in the past, it has been the mainstream to have robots perform simple tasks repeatedly, but these days, the needs for usage are diversifying, for example, by having a single robot perform multiple tasks.

Conventional use requires robots to be installed in a safe-fenced environment, separated from human work. Accordingly, there have been a number of barriers for small and medium-sized companies to introduce robots, including the need for more space that is not accessible to people, increased installation costs, and the lack of a dedicated engineer.

The advent of human collaborative robots

In 2013, the Ordinance on Industrial Safety and Health *1 were revised to allow the installation of robots without safety fences. In addition, advancements in robotics technology have made it possible to ensure human safety, such as incorporating torque sensors into the body, allowing the development of human-cooperative robots that can work collaboratively with humans even in limited spaces. Collaborative robots are now available from many robot manufacturers.

Based on the standard size of a humans’ height and 10 kg of payload capacity, there are a variety of collaborative robots, ranging in size from large ones that can carry up to 30 kg to small ones with a payload capacity of 5 kg, that can be selected according to the location to be installed and the process to be automated.

Collaborative robots are being developed not only in terms of the robot body but also its functionality so that even beginners can use them easily and intuitively.

For example, a “programming pendant,” an operating device that transmits movement to robots, can be operated like a tablet device. It also has a “direct teaching function” that can be easily handled by holding the robot body directly with your hand and moving it freely up, down, left and right. In addition, a number of products have been released that are designed to be easy for even those unfamiliar with robot operation, such as an “anti-pinching design” that prevents fingers from being caught in the gaps between the robot arms.

Additionally, the end tools such as grippers and suction hands, which are attached to the end of the robot’s arm from the wrist, are becoming easier to replace. Yaskawa is also working with various manufacturers to develop peripherals as the Yaskawa Plug & Play Kit.

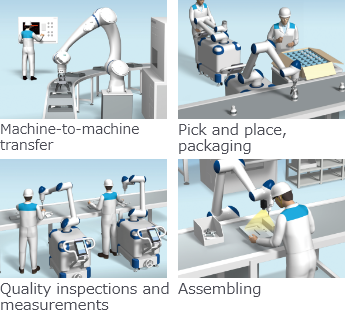

The arrival of these collaborative robots has made it possible to carry out various tasks with humans, even at manufacturing sites and processes where it was previously difficult to install robots.

< Example >

●Assembling, screwing and inspecting parts

●Sheet metal pressing in a metal working factory

●Workpiece loading and unloading for processing machines

●Robot-to-human delivery of products in food factories

etc …

*1 Notice by Japan Advanced Information Center of Safety and Health on December, 2013

Note:A separate risk assessment is required for installation without a safety fence.

Collaborative Robots of Yaskawa

Yaskawa’s cooperative robots, the MOTOMAN-HC series, are available in 10 kg, 20 kg, and 30 kg of payload capacity, and are equipped with user-friendly specifications and functions.

For example, the robot is equipped with a variety of specifications to meet customer needs, including dust- and drip-proof specifications that allow the collaborative robot body to be washed, a particular surface treatment applied to the arm surface without the use of paint to prevent the occurrence of paint chips, a path generation (path planning) function using the arm directly, and a safety feature that minimizes harm caused by human contact.

In addition, the hand-carry model, combined with a trolle that can be easily moved and set up, can be easily installed where needed, even when the production plan changes or the line layout changes.

Yaskawa’s collaborative robot, the MOTOMAN-HC series, will expand the potentials of the new manufacturing through collaboration with humans and robots.

MOTOMAN-HC10DTP

まずはお気軽にお尋ねください!

導入事例を

もっと詳しく知りたい!

導入には

どんな設備が必要ですか?

導入の予算は

どれくらいですか?

こんな使い方は

できますか?

お問い合わせ・資料請求フォーム

◆資料をご希望の方へ◆

以下の資料は、フォームにご回答いただいた後にダウンロードできます。

※資料のダウンロードには、ご回答送信後にe-メカサイトへのログイン・会員登録が必要です。

■人協働ロボットHCシリーズカタログ

■人協働ロボットHCシリーズ用途事例集

■人協働ロボットHCシリーズセットアップガイド

■人協働ロボットHCシリーズ安全対策事例集

そのほかの資料をご希望の方は、以下のフォームにご希望の資料をご記入ください。

For inquiries about the installation of our collaborative robots,