Occupational safety & health

Yaskawa strives to create a safe and healthy work environment for its employees by stipulating the health and safety of its employees in the “Yaskawa Group Code of Conduct” as follows.

Yaskawa Group Code of Conduct Guidelines

Based on this guidance, we ensure the safety and health of the workplace, and comply with laws and internal rules regarding workplace safety.

In addition, we have established a system for labor and management to manage occupational safety and health, and are working to maintain a safe and healthy working environment.

Occupational Health and Safety Promotion System

Yaskawa has appointed a company-wide general safety and health manager to oversee safety and health activities, and the Central Safety and Health Committee meets twice a year. The Committee consists of an equal number of members from labor and management, and representatives from each business site and group companies participate as observers. Based on the policies determined by the Central Safety and Health Committee, each business site and Group company determines, manages, and operates its own policies in the monthly Safety and Health Committee meetings. Specifically, they include the dissemination of disaster cases and their countermeasures, the confirmation of matters pointed out by patrols and the contents of improvements, the reporting of near-miss incidents, and measures against long working hours as well as the implementation of e-learning on health promotion to improve health literacy

Number of Employees who Participated in Health and Safety Training

We conducted the training programs below in fiscal 2023.

| Training |

Method |

No. of Participants |

| Safety and health education for new employees |

Collective training |

139 |

| Mandatory safety education |

E-learning |

497 |

| Health promotion education |

E-learning |

2,770 |

| Mental health self-care education |

E-learning |

2,869 |

Occupational Health and Safety

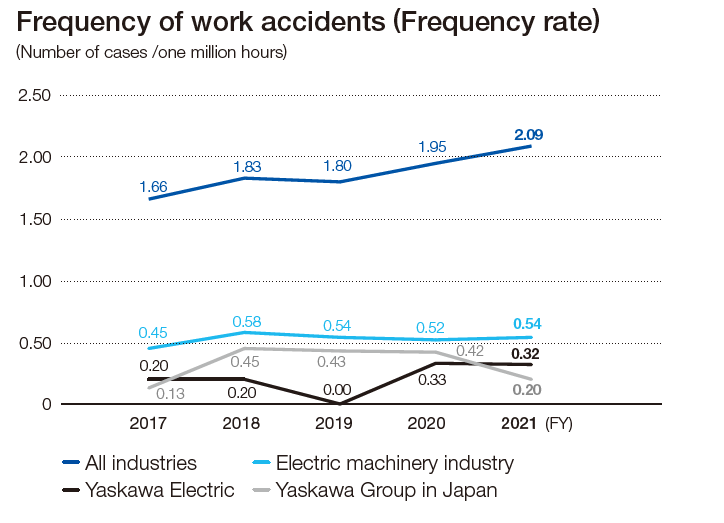

Based on the concept of an occupational health and safety management system, each workplace prepares work standards and conducts education and training, risk assessment, and accident prevention activities in daily work. We also conduct internal audits to ensure that these activities lead to the achievement of our health and safety policies and targets, and provide thorough guidance on the items pointed out by the health and safety committees at each business site to make further improvements. As a result, the frequency rate of occupational accidents in Yaskawa Electric and its domestic group companies have remained below the average for the same industry.

We have also started to assess the lost-time injury frequency rate at major overseas production sites, and found that the global lost-time injury frequency rate is somewhat high (0.53*). Major overseas production sites will also be analyzed for factors and measures will be shared to improve the lost-time injury frequency rate.

* Frequency rate of three factories in China (Shenyang, Changzhou and Shanghai) and Yaskawa India

-

*Frequency rate: Indicates the frequency of occurrence of accidents by the number of casualties due to industrial accidents per one million gross hours of actual work.

Calculation method: (Number of casualties due to industrial accidents/gross hours of actual work) × 1,000,000

Health and safety patrol

Implementation of occupational health and safety measures

・By carrying out regular patrols by industrial physicians and health managers, we are working to raise the awareness of safety among those who point out and those who are inspected.

・We are working to ensure that employees submit near misses.

・We conduct safety patrols at our plants and offices in order to enhance inspection based on expert knowledge.

・The following safety and health education programs are implemented.

Training are provided at the time of employment, when work contents are changed, when work standards are established or changed.

Safety and health education for employees within three years of employment

Safety and health education for employees handling specified chemical substances

Special education for workers engaged in dangerous or harmful work

Education corresponding to workplace accident trends

Employee Health Support

With regard to various medical examinations, we take into full consideration the related laws and characteristics of examinations, and strive to implement them organically and efficiently, from grasping the working environment and selecting the subjects, to conducting the examinations and taking follow-up measures. We provide health guidance and education focusing on lifestyle and employment support as well as prevention of work-related illness.

Mental Health Measures

We consider psychiatric disorders and disabilities, as well as other diseases, to be diseases that can occur to anyone, and provide support in terms of daily life and work as necessary.

As part of measures to deal with psychological stress, which has various effects on employees’ health and lives, we use a stress check system and provide feedback to individuals and the workplace based on the results.

For external mental health consultations, we have expanded our consultation desks to cover 24 hours a day, 365 days a year, including holidays.

Support for People on Sick Leave to Return to the Workplace

When employees return to their workplace after taking long leave due to inevitable sickness or injuries, we prepare the maximum possible physical support structure and physical environment to support them in collaboration with the individuals, as well as their superiors, the administration department, and the industrial doctor.

Region

Region

Principles & vision

Principles & vision

Procurement

Procurement

Sustainability for the Yaskawa Group

Sustainability for the Yaskawa Group

Customer satisfaction

Customer satisfaction

Supply chain

Supply chain

Social contribution

Social contribution

Compliance & risk management

Compliance & risk management