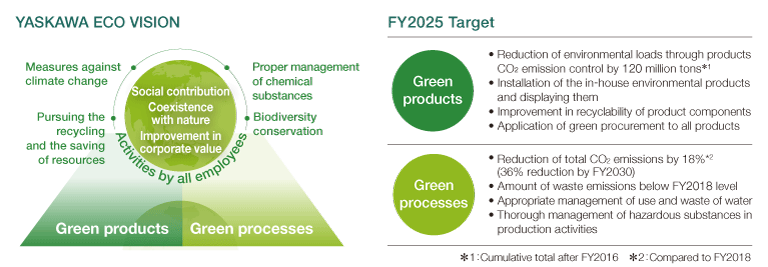

Environmental vision & targets

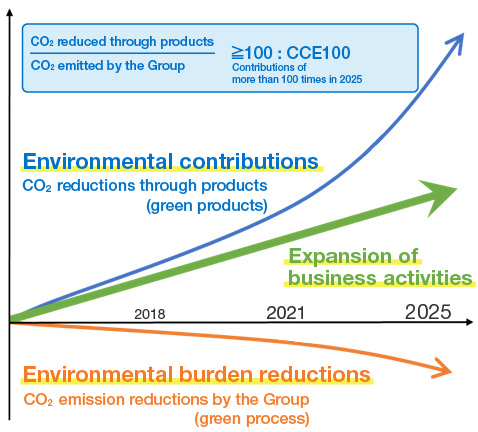

Reduction of the CO2 emissions through our products by 100 times of the amount emitted by the Group in 2025,in order to pass the bounty of the earth’s blessings to the next generation

– Promoting environmental management using green processes and green products that must go hand-in-hand –

Through our original style of environmental management, the Yaskawa Group is promoting green processes to reduce adverse environmental impacts associated with business activities and the use of Yaskawa’s green products by our customers around the world to lighten the load on the environment.

In recognition that climate change is a pressing issue that must be addressed, the Group will double down on our commitment to reduce the amount of CO2 emissions through our products by at least 100 times of the amount of CO2 emissions emitted by the Group in 2025 to continuously improve our corporate value.

The CCE100 value for FY2024 was 93.6. The introduction of solar power in China during FY2024 is expected to make a significant contribution towards achieving the CCE100 target in FY2025.

*1 Contribution to Cool Earth 100

Yaskawa Group’s Vision and Long-term Plans for the Environment

Yaskawa makes contributions to the environment by reducing the burdens that result from its business activities (green process) at a greater rate, and by reducing the burden on the ecosystem with its products (green products) leveraging its technology to enhance the environmental performance.

As climate change poses a number of problems on a global scale, we are striving to enhance corporate value by pursuing sustainability through multifaceted environmental activities, with a focus on reducing CO2 emissions through products that utilize one of our company’s core competences of power conversion.

2050 CARBON NEUTRAL CHALLENGE

The Yaskawa Group aims to reduce net CO2* emissions (scope 1* + scope 2*) to zero, achieving carbon neutral in our business activities by 2050. To achieve this goal, we will reduce CO2 emissions in 2030 by 51% from 2018 levels.

By 2030, we will also reduce CO2 emissions in the upstream and downstream of the supply chain (scope 3*) by 15% from 2020 levels.

This 2030 target was recognized as a “1.5℃ target” by SBTi, an international initiative which verifies that corporate CO2 reduction targets are in line with scientific evidence.

*CO2:Includes carbon dioxide and other greenhouse gases, such as fluorocarbons.

*Scope 1:Emissions primarily from using fuels (direct emissions)

*Scope 2:Emissions from using purchased electricity and heat (indirect emissions by power companies and other entities)

*Scope 3:Indirect emissions other than scope 1 and scope 2 (emissions by other companies related to the activities of the business)

- SBTi certified 1.5℃ target

- – By 2030, the Yaskawa Group will reduce net business CO2 emissions (Scope 1 + Scope 2) by 51% from 2018 levels.

- – By 2030, we will also reduce CO2 emissions in the upstream and downstream of the supply chain (Scope 3) by 15% from 2020 levels.

- Note: Baseline year emissions

- – Scope 1+2: 54,504 t-CO2 (FY2018)

- – Scope 3: 50,439,000 t-CO2 (FY2020)

Midterm Environmental Plan (FY2023 to FY2025) Targets

For our Midterm Environmental Plan (FY2023 to FY2025), we are putting even more effort in our activities to conserve resources. In addition to our FY2025 targets that aim to achieve the objectives stipulated in our Long-Term Environmental Plan, we have added a target to reduce water consumption.

Midterm Environmental Plan (FY2024) Targets and Results

Self-evaluated achievement ratios to targets: ◎ – 130% or more, 〇 – 100% or more, △ – 50% or more, × – under 50%

Region

Region

Principles & vision

Principles & vision

Procurement

Procurement

Sustainability for the Yaskawa Group

Sustainability for the Yaskawa Group

Customer satisfaction

Customer satisfaction

Supply chain

Supply chain

Social contribution

Social contribution

Compliance & risk management

Compliance & risk management