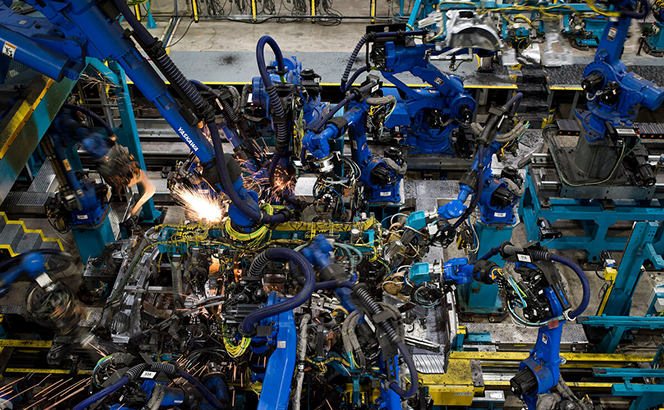

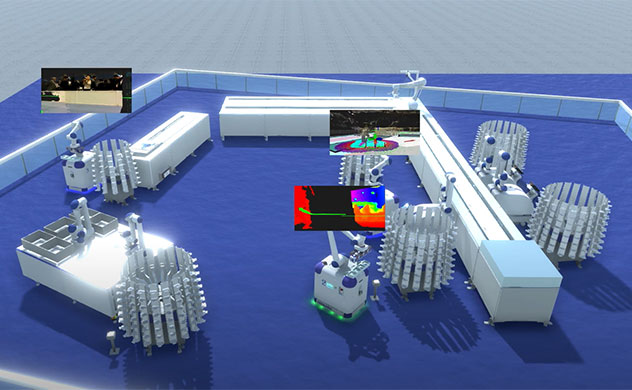

Robotic System Setup

Industrial robots are usually shipped without tools / end effector at tip from the wrist of the robotic arm. System engineering is required at each customer site according to what they want to do. Install the end effector according to the purpose of the suction cup for sucking the workpiece with air, gripper for gripping the workpiece, welding tool, etc. We also propose system engineering for the entire facility, including peripheral equipment, when it is incorporated into a factory line, rather than just a robot.

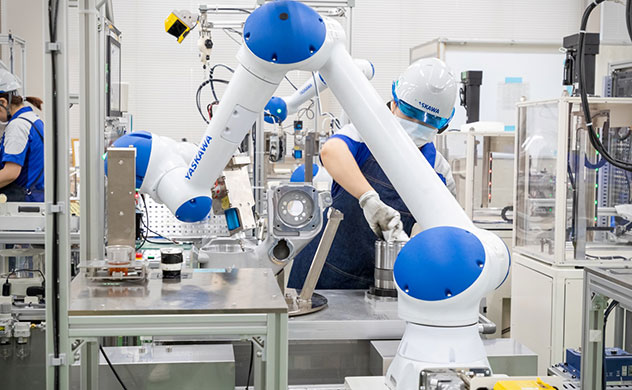

Teaching

A programming pendant connected to a robotic controller generates a motion path while operating an industrial robot. In collaborative robot, you can create a program by holding the robotic arm directly and memorizing the point by direct teaching. This way, even novice robots can operate with intuitive movements and reduce teaching time greatly.

Safety Design of Robotic Systems

Industrial robots differ from other industrial machines in that they have advantages such as a wider range of motion than the installed area, high-speed and high-power arm movements, and diverse and autonomous movements. Whereas, if precautions are ignored or the robot is used incorrectly, there is a risk of that operators may get serious injury accidentally by entering the operating area while the robot is in operation or may cause damage to the equipment.

Furthermore, the robot is not a complete end product; it is a partially completed machine. The robot cannot be put into operation until the user has completed to program tasks for robots that integrated with end-effector, sensors, and peripheral devices, and built robot system that has been incorporated into production equipment. The robot system is designed by the user who purchased the robotics products and a system designer (system integrator).

In particular, please pay attention to the following points when designing a robot system.

- YASKAWA provides no guarantees about the safety of the end effector, workpiece, and peripheral devices that make up a robot system prepared by the customer. The robot system designer must design the system in conformance with safety standards so that sufficient safety can be ensured throughout the entire system. (see ISO 10218-2 (JIS B 8433-2))

- To prevent equipment damage and injury to operators and others during robot operation, install a safety fence that complies with ISO 12100 (JIS B 9700) and ISO 14120 (JIS B 9716). In addition, install an interlock device (e.g., safety plug) that turns the servo power off at the entrance and exit to the safety fence when the door is opened, and make sure the robot system cannot perform automatic operation when the door is open. If there are areas where there is no safety fence in place, e.g. if the application requires frequent access to the machine, working with the machine, or good visibility of the machine or process, use an electro-sensitive protective equipment (e.g., photoelectric sensor, safety light curtain, etc.) to make sure that the robot stops its operation if the operator enters its operating range. Before starting operation, always activate the interlock device (e.g., safety plug) or the electro-sensitive protective equipment (e.g., photoelectric sensor, safety light curtain, etc.) and confirm that the servo power is turned off. For the installation methods, please refer to the instructions for each product.

-

For safety functions such as external emergency stops, safety plugs, or

protective stops by an electro-sensitive protective equipment, please

refer to the “Safety Functions” chapter of the instructions for each

product when designing the robot system.

YASKAWA robot controllers have the following safety functions. External

hold signals and general-purpose input output signals are not included

in the following safety functions.

- Emergency stop button inputs (robot controller/pendant)

- Enable switch input (pendant)

- Safety fence interlock signal input (safety plug)

- External emergency stop button input

- Safety logic circuits