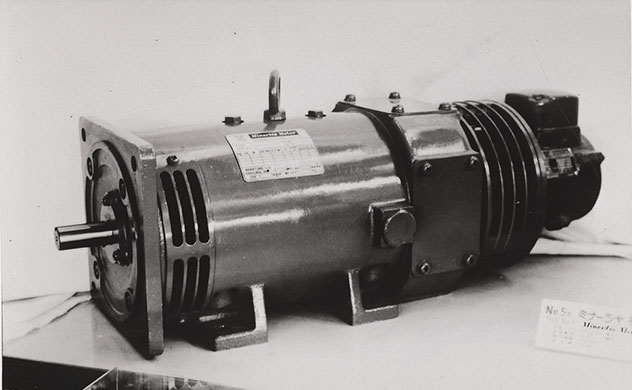

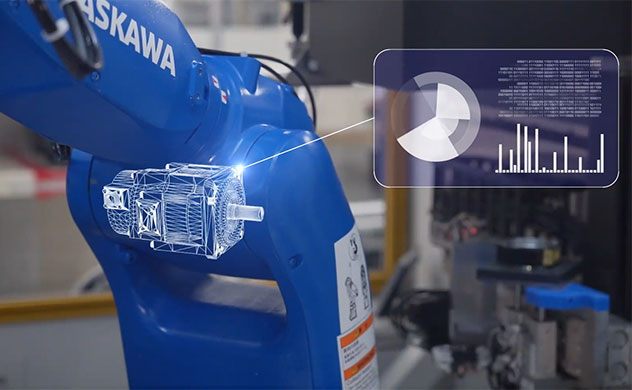

Minertia motor

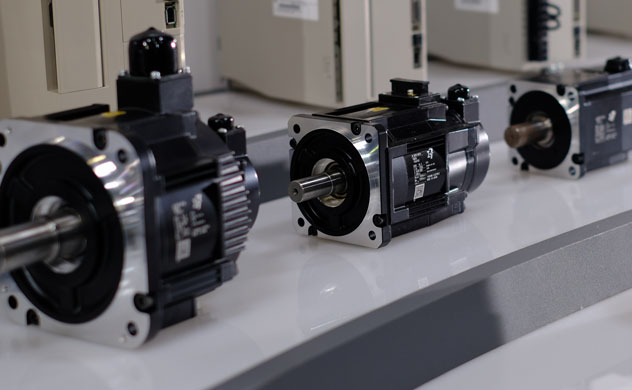

In the 1960s, Yaskawa developed a succession of innovative DC servo motors, and in 1983, AC servo motor was launched, creating a new wave in the motor industry. And now, nearly 30 years later, almost 100% of factory automation (FA) uses AC servo motor.

While a general motor is designed to work by continuously rotating the load, a servo motor is designed not only to rotate the load but also to respond accurately and quickly to the target.