Preventive maintenance using YASKAWA AC Drives (inverters)

The YASKAWA AC Drive (inverter) detects unusual operations in both the AC drive (inverter), as well as machinery and equipment and informs users before failures occur. This allows users to develop effective maintenance plans to improve productivity and enable the continuous operation of machinery and equipment.

Informs users about deteriorating parts and unusual operations in machinery and equipment |

Compatible models: GA700, GA500 |

|---|---|

| Support Tool: DriveWorksEZ |

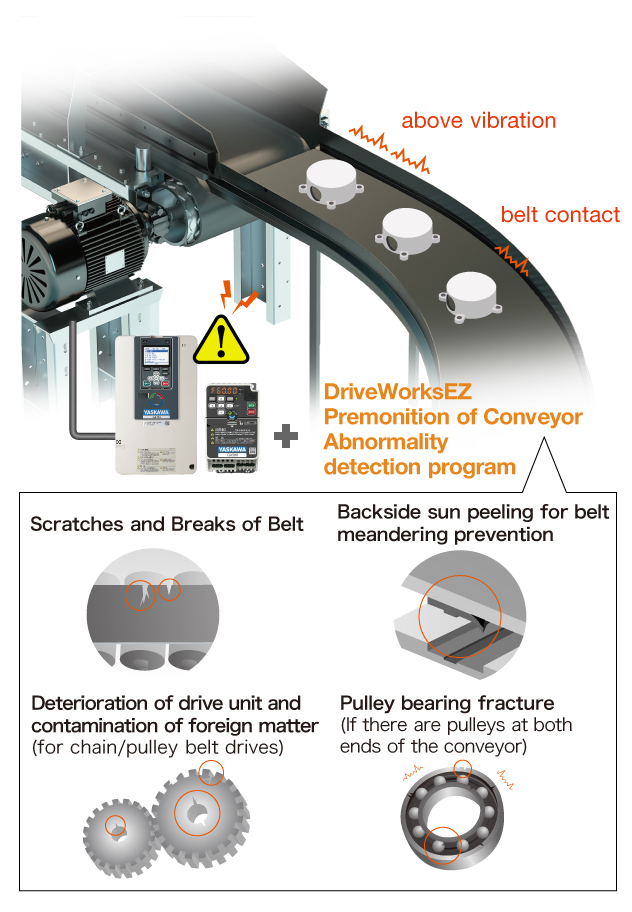

■ Predictive failure detection of conveyor

Data input to the torque monitor on drives varies according to the deterioration of the conveyor belt, pulley bearings and other mechanical parts. The drives diagnose changes in torque, and noties the operator before the conveyor breaks down.

■ Fan flter clogging predictive detection

Data input to the current monitor on drives varies according to the degree of fan lter clogging and accumulated contamination. The drives diagnose changes in current, and noties the operator of the timing to clean the fan lter.

■ Other applications

Noties users of the optimal timing to replace AC drive (inverter) parts in advance |

Compatible models: GA700, GA500 |

|---|

The four main limited lifetime service parts that determine the life of the AC drive (inverter) vary depending on the installation environment and usage of the AC drive (inverter). A real-time diagnosis and notication to users before a problem occurs allows the factory to avoid suspending operations due to the failure of the AC drive (inverter).

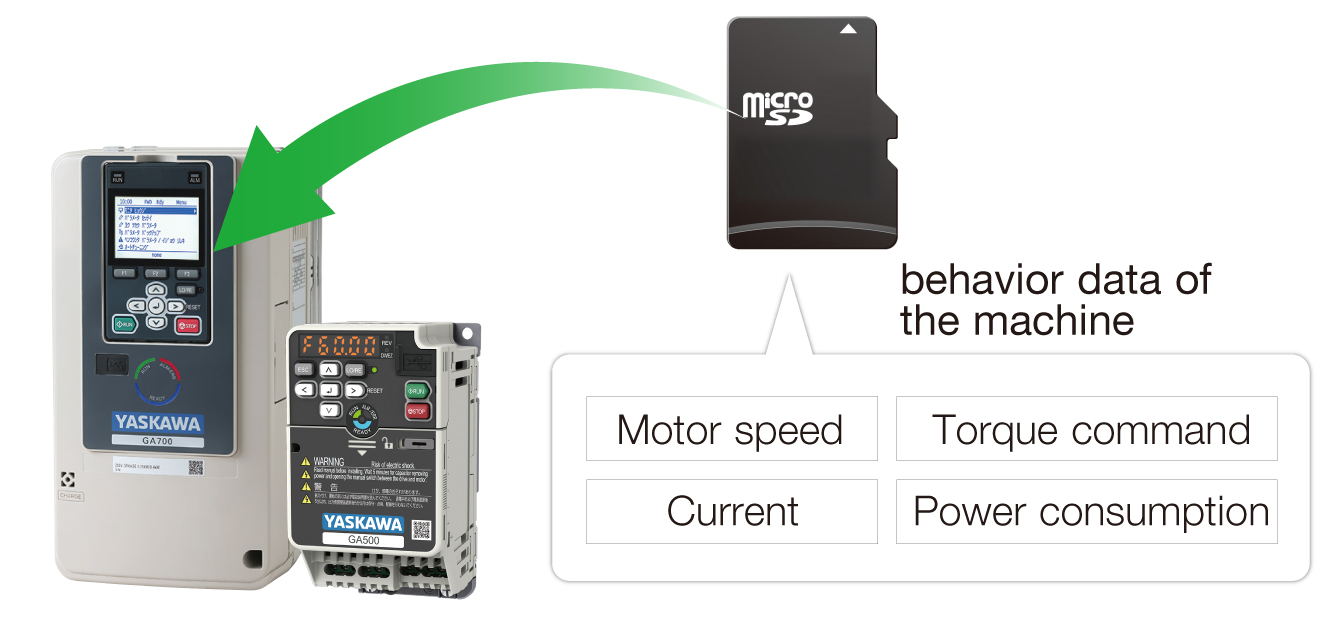

Collect behavior data of the machine without measurement instruments in real time |

Compatible models: GA700, GA500 (Option) |

|---|---|

| Support Tool: DriveWizard |

By attaching a microSD to the AC drive (inverter), data can be logged at high speed while the production line is in operation. The machine status can be understood without using a controller or other instrument.